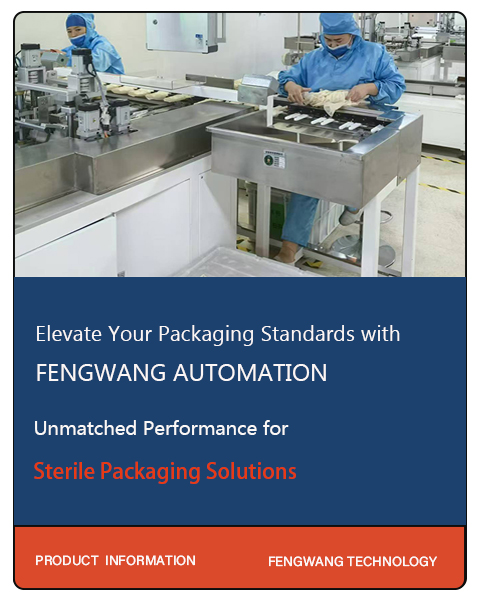

About Surgical Gloves Packing Machine

Surgical gloves packing machine is a fully automatic packaging equipment for sterile surgical gloves. This unit is equipped with a high quality servo drive and pneumatically controlled charging tool. Due to the aseptic properties of surgical gloves, the glove packaging process is different from that of ordinary disposable latex gloves.

The surgical glove packing machine is designed to connect the surgical glove inner wallet packing machine and the four-sided sealing machine using a synchronous servo drive system at speeds of up to 75 bags/min. Fengwang surgical glove packing machine effectively improves the production efficiency and reduces the manpower for surgical glove manufacturers by 80%.

How Surgical Glove Inner Wallet Packing Machine Work?

The surgical glove premium packing line machine can operate as a single inner purse packing line or a complete inner purse and outer bag packing line. As a complete surgical glove packaging line, it requires about 10 operators to package at a rate of 4,500 packs/hour.

Features of Surgical Glove Packing Machine

Surgical glove packing machine is a high yield surgical glove inner wallet packing machine with synchronous servo drive system, starting from paper roll form. With the input size and a simple conversion kit, flexible options are available to produce wallets of different sizes. Wallets can be in a standard long format or inline, double-fold format. It accepts blank paper rolls with inline printing or accepts pre-printed paper rolls by printing.

- Reduce manpower, increase production

- Continuous sealing process, eye tag registration.

- The machine is designed in a modular concept for easy integration with other equipment.

- Large touch screen, PLC system, easy to operate.

- Cutting accuracy ±2mm

- Print online up to an entire sheet of paper.

- Mark the cut point of the preprinted paper with your eyes.

- The machine adopts PLC and touch screen for operation control.

- The temperature sensing module detects the sealing heating and then sent to PLC for processing and control after analog-to-digital conversion. High-precision temperature control.

The sterile surgical glove packaging field continues to evolve, driven by advances in materials science and technology. Lead this change through innovative antibacterial packaging materials, smart packaging with sterilization metrics, and eco-friendly options. Our commitment to sustainable practices not only enhances safety, but also meets the growing demand for environmentally friendly solutions in the healthcare industry.

The Importance of Sterile Surgical Glove Packaging

Sterile surgical glove packaging is a testament to the meticulous attention to detail required for healthcare. Being at the forefront of this critical industry combines advanced materials, cutting-edge sterilization technology and rigorous quality control. In healthcare, where precision and cleanliness are crucial, the packaging of surgical gloves plays an integral role. Sterile surgical glove packaging is essential to protect patient health and ensure the highest standards of infection control.

Surgical gloves are the primary barrier between healthcare professionals and potential sources of infection, protecting patients and medical staff from cross-contamination during surgery. The effectiveness of these gloves depends not only on the quality of their materials, but also on the sterility of their packaging. Contaminated gloves can act as vectors for pathogens, leading to post-operative infections, extended hospital stays, and increased medical costs. Therefore, keeping them sterile from the point of manufacture to the moment they are worn in the operating room is essential for patient safety and high-quality healthcare delivery.

Surgical gloves excellence ensures the safety and well-being of patients and healthcare professionals.