Fengwang PVC Glove Machine

Fengwang Automatic PVC glove-making machine combined with the latest technology which is high automation and high production capacity.

Fengwang PVC plastic gloves-making machine adopts continuous production and direct impregnation method, and the same production line can produce different kinds of products at the same time. Product appearance of uniform quality and beautiful color is popular among most glove customers.

Fengwang PVC Gloves Manufacturing machine

Fengwang Technology has been specialized in PVC glove production line for 20 years and has rich experience in automatic plastic glove making machine manufacturing.Always able to meet the various needs of customers.

Remove the glove completely from the glove formers and count.

The gloves are packed in a box and closed, automating the full process.

Partners of Fengwang in China are Intco, Bluesail, Hongray and so on.

Depends on raw materials of gloves customer wants to build.

Installation Project

The utility of Fengwang vinyl glove machine is second to none in the machinery industry.The entire PVC glove production line installation is divided into several parts, the following is a detailed introduction.

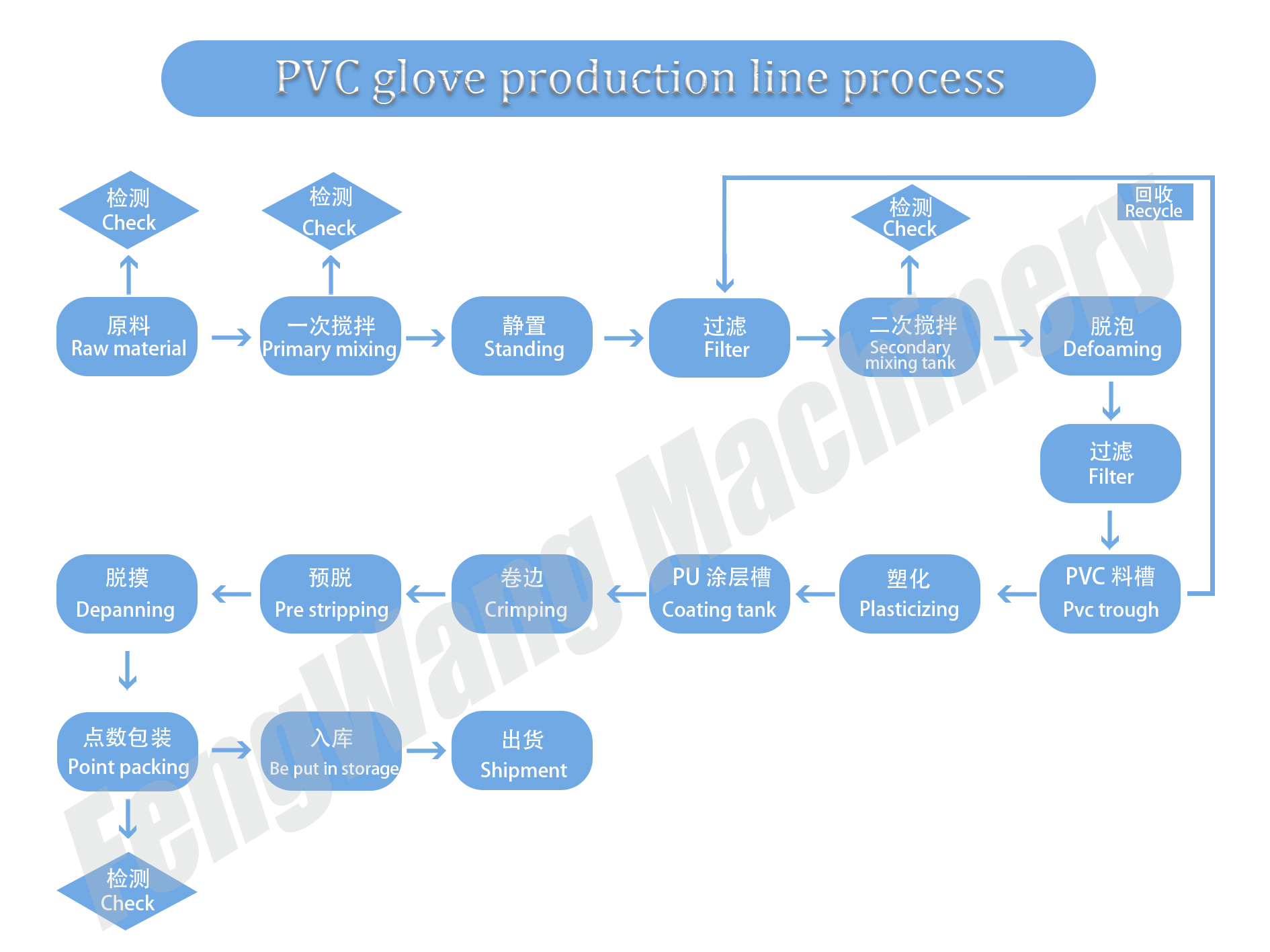

PVC Glove Production Line Process Flow

PVC gloves are also called vinyl gloves, and the general production process is divided into the following parts:

Dipping: The glove formers are dipped in the raw material in an orderly manner.

Beading: The beading machine is responsible for rolling up the cuffs.

stripping: The stripping machine quickly and orderly removes the finished glove from the glove formers.

Packaging: Product packaging is carried out after product quality inspection.

Fengwang Custom PVC Glove Production Line Serious

Plastic glove manufacturing machines require real-time and comprehensive control of the use process in order to stabilize mass production. In particular, the use of medical powder-free PVC glove machines has higher requirements.

The speed of the production line of disposable plastic gloves is a key factor affecting the production of gloves. PVC gloves production line speed is too fast will affect product quality.

Therefore, how to control the whole process of plastic gloves making machine has become the key to determine the competitive advantage of enterprises.

PVC Gloves Production Line Common Problems and Solutions

The influence of disc brush on glove formers —- the two sides of gloves will be uneven, and the disc brush diameter is related to the glove production line speed. In China, the largest disc brush diameter is 16MM, while the general diameter is 14MM. The smaller the disc brush, the faster the line speed and the increase of the unevenness.

PVC gloves production line hand mold bearings —- need frequent lubrication. If the bearing does not rotate normally or is stuck, the glove will have mold impact resulting in glove holes and thickness inequality.

Effect of oven temperature on gloves—- The hand mold should be gradually heated in the oven. Too high temperature at the beginning will cause the slurry on the hand mold not to be homogenized and solidified, and the thickness of the gloves is uneven. In addition, the outer layer of the glove will be solidified first, and the inner layer of plasticizer will evaporate and remain inside the glove, causing bubbles and affecting the plasticizing performance of the glove. The temperature of the oven at the back directly affects the degree of plasticization of gloves. If the overall oven temperature is too low, the gloves cannot be fully plasticized, the strength is low, and the fingers are easy to break.

About the beading —- The appropriate temperature for the rolling is 100-110 degrees, the temperature is too high to roll into rotten edges, the temperature is too low to roll the top. The S-shape of the edge is related to the liquid level of PU wet powder, the position of the edge and the speed of the edge close. The rolling edge is too thick and too fine, which is related to the position of the rolling edge, the impurities of the rolling rod, and the liquid level of the PVC slurry tank.

Gloves have torn edge —– fast speed, low cooling temperature of the rolling edge, insufficient maturation of gloves. The reason should be these aspects, such as the speed of the rolling stick is slower than the speed of the PVC glove production line, so it is easy to tear the edge.

Bubbles —-PVC powder quality is not up to standard, too many large particles. PVC powder moisture seriously exceeded the standard. Slurry mixing is not uniform, the surface solvent is too much. Vacuum removal effect is poor. Discharge speed is too fast. Large drop between discharge filter and trough. The temperature of the slurry is too low, the surface tension of the bubble is too large, and the hand model is easy to produce bubbles. The dip speed of the hand mold is too fast, and air is too late to be removed, resulting in bubbles, etc.

Gloves are too thin or too thick —- low temperature slurry, poor fluidity on hand models. The Angle of entry into the oven is relevant. Hand mold bearing damaged or not flexible rotation. The slurry in the tank is stratified.

Pinhole —- hand model itself has trachoma. There’s something dirty on the hand model. PVC powder or DOP moisture is high, and PVC powder has large particles too much. Mixing is not uniform, the surface solvent is too much. The defoaming standing time is not enough. The production line is not clean enough.

Gloves surface pattern or water pattern —- choose better PU. The droplet is too short after PU immersion. The hand model is dirty and needs cleaning.

Sticky gloves —- Distinguish between sticky on the outside and sticky on the inside. External stickiness needs to be considered whether there is too much plasticizer, too high temperature at the glove stripping machine or gloves not fully plasticized and dirty hand molds. The internal sticky needs to be considered whether PU or wet powder has low solid content, and the prestripper brush needs to be cleaned. Both inside and outside are sticky considering the separation of ESO etc.

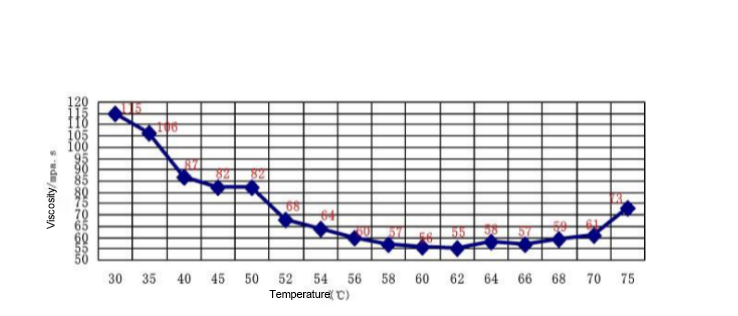

PVC Slurry and Temperature Curve:

The viscosity of PVC slurry gradually decreases with the increase of temperature, but when the glass transition temperature tends to the gel temperature, it will rise rapidly in a short time, or even instantly gel.

Remind: How to Improve the Quality of PVC Gloves?

The weight of the glove determines the cost of the glove, the weight depends on the thickness of the glove, and the thickness depends on the viscosity. Precise viscosity control is the key to control glove quality and reduce cost.

In summary, the operation of each process will affect the of the final glove quality. In the production process, each process must be strictly controlled, according to the performance of the product and the slurry, to determine the appropriate process conditions, so as to improve the quality of gloves.