Fengwang Nitrile Gloves Production Line

Nitrile glove making machines are divided into single model production line and double model glove manufacturing equipment, and the glove production line is long.

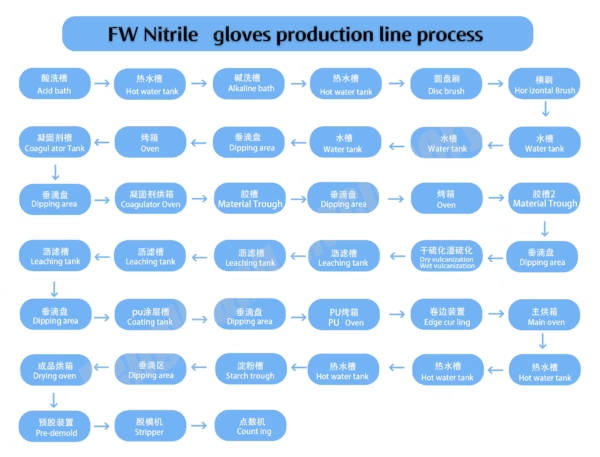

Therefore, the process control requirements for nitrile gloves are higher. Technical personnel are required to understand the entire nitrile glove manufacturing process.

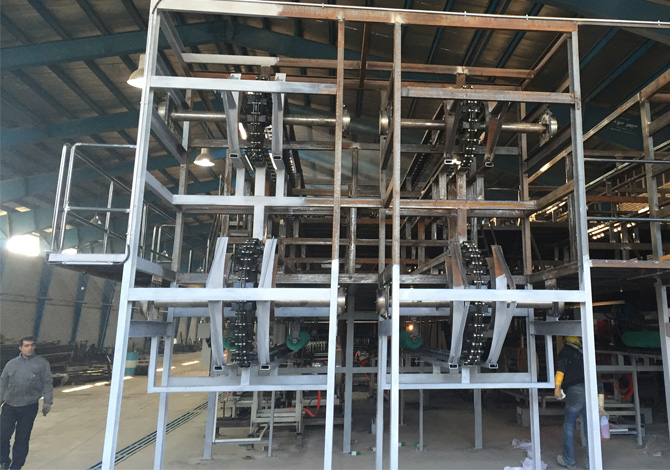

Fengwang Machines to Make Nitrile Gloves

It automatically removes the glove from the glove formers.

Remove the gloves resting on the fingertips,stack them for counting.

The gloves are packed in a box and closed, automating the full process.

Partners of Fengwang in China are Intco, Bluesail, Hongray and so on.

Depends on raw materials of gloves customer wants to build.

Your Nitrile Glove Production Line Manufacturer

Production Processes for Nitrile Glove Production Lines

How to Manufacture Nitrile Gloves

Fengwang not only provides drawings for your glove making equipment design, installation, post-commissioning, after-sales maintenance services, but also provides glove machinery technical process guidance, which is a very important step in the nitrile gloves production line.

Resource to Customize Nitrile Glove Production Line?

To make contact →Engineer confirms the size of customer’s workshop→Desing plant layout plan

→Design product line drawings and confirm by both parties

→Buy steel, manufacture tank, tank and other parts for production line

→Shipment to customer plant

→The engineer came to the factory to guide the installation

→Commissioned finished product

Does Your Glove Factory Face These Problems?

- Want to buy hand gloves manufacturing machine but don’t understand the process flow and layout of nitrile gloves manufacturing plant?

- Can’t the existing production line meet the ideal production speed?

- Existing disposable glove manufacturing equipment want to change to latex production line?

- Optimize existing hand gloves machine but do not know hand gloves making machine cost?

- Is there a problem with the quality of the disposable glove manufacturing?

Fengwang Custom Nitrile Glove Production Line Serious

Fengwang nitrile glove machine for sale.We can do the whole nitrile glove production line, also a single machine in the production line, including stacking machines, stripping machines, packaging machines, beading machines, glove formers, glove formers holders, intelligent refueling machines, etc. Fengwang provides you with the ultimate solution when you raise the problems you encounter in the production of gloves.

Why 1000+ Customers Choose Fengwang?

Fengwang provides one-stop service.Customers can provide site information or even an idea, we can specially design, manufacture and install for customers. After installation, we will train the customer on the machine operation process until they can fully master the production process.

20 years of experience in foreign trade enables in-depth understanding of customer needs. Constantly update the latest ideas of machine manufacturing to meet the latest ideas of customers on machines. Fengwang has always been at the forefront of technology in the nitrile gloves machinery.

Our factory is a large modern workshop, which is equipped with a wide range of modern machining equipment and loading equipment to prevent the machine from being worn out in transit.All in the interests of customers.

Fengwang thanks customers who are enthusiastic about the machine and support customers to visit our factory. At present, our customers come from Iran, Turkey, Ethiopia, Malaysia, Vietnam, Algeria and so on. We like to make friends with people from more countries.

About Nitrile Gloves Production Line

- Parameter Table

|

SINGLE MODEL

|

||||

|

MODEL

|

MACHINE SIZE

|

CAPACITY

(pcs/hr) |

Heat consumption (10,000 kcal/hr)

|

POWER(KW)

|

|

FWSM60

|

60*2.2*9m

|

3,360-4,368

|

40

|

178

|

|

FWSM80

|

80*2.2*9m

|

7,440-9,672

|

90

|

185

|

|

FWSM100

|

100*2.2*9m

|

9,480-12,324

|

115

|

210

|

|

FWSM120

|

120*2.2*9m

|

12,240-15,912

|

150

|

240

|

|

FWSM140

|

140*2.2*9m

|

14,400-18,720

|

180

|

290

|

|

FWSM160

|

160*2.2*9m

|

16200-21,060

|

200

|

320

|

|

FWSM180

|

180*2.2*9m

|

18,600-24,180

|

230

|

360

|

|

DOUBLE MODEL

|

||||

|

MODEL

|

MACHINE SIZE

|

CAPACITY

(pcs/hr) |

Heat consumption (10,000 kcal/hr)

|

POWER(KW)

|

|

FWDM80

|

80*2.4*12m

|

13,200-17,160

|

160

|

195

|

|

FWDM100

|

100*2.4*12m

|

18,000-23,400

|

220

|

223

|

|

FWDM120

|

120*2.4*12m

|

22,800-29,640

|

280

|

250

|

|

FWDM140

|

140*2.4*12m

|

24,000-31,200

|

290

|

300

|

|

FWDM160

|

160*2.4*13m

|

31,200-40,560

|

380

|

330

|

|

FWDM180

|

180*2.4*13m

|

38,400-49,920

|

460

|

380

|

|

FWDM200

|

200*2.4*13m

|

43,200-56,160

|

520

|

400

|

|

The above specifications are for reference,Production lines can be customized according to your requirements.

|

||||

You should prepare workshop, water lines, electrical wiring, compressed air (if you need, we can help you buy an air compressor). We can provide workshop layout drawings according to your workshop.

The lead time for a production line is about 90 days. (According to the actual order situation)

Customers can choose to pay in installments, we accept T/T, platform direct payment, etc.

China (Bluesail, Intco, Zhonghong, Hongray, Wanli), Malaysia, Turkey, Vietnam, South Korea, Southeast Asia and other countries.

Choose the product you like, or send us your requirements, and our engineers can create a project and quote for you. (Then, confirm all details and sign the contract. You can make an advance payment, and we will start purchasing raw materials for production. The product will be shipped according to our agreement. )

Of course, we are located in Shijiazhuang, China, you can take a plane to Shanghai, then take a high-speed train or plane to Shijiazhuang, we will arrange a driver to pick you up. Welcome to visit our factory.

We will provide installation drawings and videos. We can also send professional technicians to your company to guide the installation of the machine and train your staff on-site until they can operate the machine independently.

We need to know how much production space, how much production capacity, the need for new production lines or modifications, a certain machine, or just maintenance, and so on?

For our customers, our machines are very durable and have a 1-year warranty. Some machines provide remote program upgrade services. Also, after-sales services includemaintenance,on-site training, and more.

From designing,debugging to delivery, we will send related pictures and videos for customers to track the production process. We will also update you when our engineers complete the development of special requirements.

We still offer our repair services to you even when the warranty time is over. This service does not have an expiry date.

If you encounter any problem with nitrile gloves manufacturing machine, we can offer:

User manual in English

Operation video

24/7 online support

You can also send your technician to nitrile gloves making machine manufacturers to attend the skills training to operate and maintain your new nitrile glove machine.

Learn More About Nitrile Glove Chemistry

Nitrile gloves are popular in the disposable gloves market which is related to the chemical properties of nitrile gloves themselves.

Nitrile gloves are made of nitrile synthetic material without the protein contained in the latex which can easily make humans allergic. Nitrile gloves are not only resistant to acid and alkali, grease, but also non-toxic and tasteless.

This makes nitrile gloves in the production and use of the following advantages:

1. Selected high-quality material ratio

2. Soft and comfortable non-slip

3. Strong fit

4. Flexible operation.

Nitrile raw materials are made from emulsion polymerization of butadiene and acrylonitrile without phthalates. This makes nitrile gloves with good properties such as cleaning, antistatic, aging resistance, oil resistance, good tensile properties and puncture resistance, wear resistance.

Nitrile glove shape can be designed according to the human hand with great sensitivity to use. Completely fit the finger to be more widely used.

Blue pigment was added to raw materials,as a result no finished product was released without fading and no effect on the product. The low ion content of nitrile gloves is due to the fact that it is produced with 100% synthetic nitrile rubber.

Nitrile gloves with their unique properties quickly attracted the interest of the medical community and the food processing industry. And gradually becoming an interesting alternative to natural rubber with their unique wear and cutting resistance as well as suitable properties.

Fengwang customized nitrile glove production line

Disposable gloves market competition pressure is greater, in the mature stage of glove factories need to constantly update their own manufacturing machines, more and more automated high-tech equipment will reduce time costs and labor costs to increase profits.

As a new entrant in the glove industry to win a share in the existing market, it needs strong financial strength and advanced technical force. Especially in recent years, the number of new factories entering the disposable gloves industry, especially high-end nitrile gloves, has continued to increase, nitrile gloves manufacturing plant cost is expensive,and there are relatively many competitors. How to choose a scientific and reasonable nitrile glove manufacturing equipment can save nitrile gloves manufacturing plant cost and create more value at the same time?Please contact our technician on the right.