Nitrile Glove Application

- Nitrile gloves are widely used in various industries due to their special material properties.

- Food handling.

- Research, agriculture, healthcare and other industries.

- Watches, precision electronic components and instrument installation, scientific research laboratory and other fields.

Nitrile glove manufacturing machines need to scientifically match disposable nitrile glove raw materials before operation. The main advantages of high-quality nitrile gloves are high strength and high flexibility. They are mainly suitable for workstations with continuous exposure to liquid chemicals, such as chemical storage, natural or unnatural experiments, etc.

Disposable nitrile gloves come in a variety of colors and are suitable for different occasions. Not only are they easy to put on, they’re also very strong. They are immune to acids, antacids, wear, oils, and static electricity. Because nitrile gloves do not contain water-soluble proteins, and after modification there are no chemical deposits, you can avoid the skin allergy problems caused by latex gloves.

Nitrile Gloves Physical Properties

Elasticity and fit: Nitrile gloves have good elasticity and can be tightly fitted to the hand. Although slightly less flexible than latex gloves, they are sufficient to meet most operating requirements. When wearing nitrile gloves, they can naturally stretch and contract with the action of the hand without causing obvious bondage to the hand. They can also be better restored after the completion of the operation, providing a comfortable wearing experience.

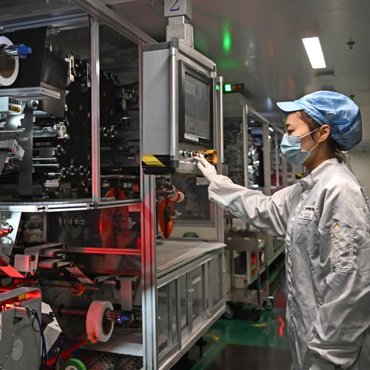

Nitrile Gloves Production Process

Nitrile Gloves Double Mode Production Line Video

Nitrile Gloves Double Mode Production Line Video

Ingredients: The nitrile latex is mixed with other additives such as nano zinc oxide, sulfur powder, titanium dioxide, accelerator, antioxidant, liquid potassium, etc., according to a certain proportion.

Glove former cleaning: First put the glove former in an acidic solution with a pH value of 3-5, and then clean it in an alkaline solution with a pH value of 10-12. After rinsing, the glove former must be dried in the oven for better impregnation and other processes.

Coagulant impregnation: Immerse the cleaned glove former in the coagulant solution for 1-2 minutes, and then enter the oven to dry, so that the coagulant forms a uniform film on the surface of the glove, which helps the adhesion of nitrile latex.

Nitrile rubber impregnation: the hand model after drying is impregnated twice by nitrile latex impregnation solution. The first impregnation of 30-60℃ nitrile latex impregnation solution 0.5-1 minutes, and then put into the oven at 95-115℃ to dry; Impregnate the nitrile latex at the same temperature for a second time for 20-40 seconds, and then dry, so that the surface of the hand model is evenly attached to the nitrile rubber film.

Leaching, beading, and vulcanization: The dried product is leached to remove impurities and unreacted substances, and then the lip curling operation is carried out to shape the mouth of the glove. It is then placed in a vulcanization box and heated for vulcanization at 110-130 ° C to improve the physical properties and chemical stability of the gloves.

Cleaning and stripping: After the vulcanized film is cooled, it is cleaned with chlorine water and water in turn, and then the film is repeatedly cleaned in deionized water. After the hand mold into the automatic stripping machine to remove the gloves, packaging, and storage.

Fengwang – Professional Nitrile Glove Manufacturer

As a supplier of nitrile glove making machines for 20 years, we are committed to the development of nitrile glove production lines to optimize the production process of nitrile gloves, improve production efficiency, and reduce labor costs.

Fengwang Service Advantage

Shijiazhuang Fengwang Technology not only provides high-quality automatic nitrile glove production equipment, but also provides pre-sale, sale and after-sales services, and provides customers with a full range of more professional and convenient modern services.

Pre-sales service: to provide professional technical support services, to provide customers with the best equipment selection scheme.

On-sale services: Provide factory workshop drawings design, machine drawings and specific spare parts quotes, transportation and logistics tracking, equipment installation, commissioning, training and other services to ensure the normal operation of equipment and stable production of high-quality nitrile gloves.

After-sales service: Provide equipment warranty, maintenance, upgrade and other services to provide customers with long-term technical support and service guarantee.

Shijiazhuang Fengwang Technology Products Mainly Include

- Glove production line: Nitrile glove production line, latex glove production line, PVC glove production line, household glove production line, TPE/PE glove production line, medical glove production line, surgical glove production line.

- Glove production machine: glove packing machine, surgical glove packing machine, glove stacking machine, glove stripping machine, glove watertight test system, glove beading machine, plastic glove making machine, Glove scrap picker, intelligent oiler.

- Spare parts: ceramic glove former, stainless steel glove former, glove former holder, glove production line sprocket, etc.

Fengwang nitrile glove making machine has an advanced production process and technology, including the following features:

1. High efficiency and energy saving: Automatic nitrile glove production machinery adopts an advanced impregnation system, batching system, chain conveying system, and frequency conversion system, which can achieve efficient and energy-saving production mode, thus effectively reducing production costs.

2. Stable and reliable: The overall frame of the glove production line is made of steel structure, and the spare parts have been precision processed and strictly tested to ensure the stability and reliability of the nitrile glove making machine.

3. Easy operation: nitrile glove making machine is simple to operate, such as touch screen control, one-button switch control machine and so on, which greatly reduces the difficulty of operation and personnel training costs.

4. Versatility: nitrile glove making machine can be adjusted and modified according to different production needs, with strong adaptability and flexibility.

.