Fengwang Latex Glove Machine

● Surfactant coagulant, the film formation is more uniform

● Two production lines: single former and double formers

● Fully automatic and semi-automated according to custom requirements

● The produced gloves are worn smoothly and prevent adhesion

● Glove defect rate is low

● If there is a fault, it can be shut down at any time

Fengwang Latex Gloves Manufacturing machine

Fengwang is a latex gloves machine manufacturer.Latex gloves manufacturing machinery are all manufactured in accordance with international mechanical standard specifications with complete certificates, and can be exported to Europe, the Middle East, Southeast Asia, North America, South America and other regions.

It automatically removes the glove from the glove formers.

Remove the gloves resting on the fingertips,stack them for counting.

The gloves are packed in a box and closed, automating the full process.

Partners of Fengwang in China are Intco, Bluesail, Hongray and so on.

Depends on raw materials of gloves customer wants to build.

Fengwang Latex Gloves Manufacturing Machine Features

Design according to customer needs a different length, height, and cost models.

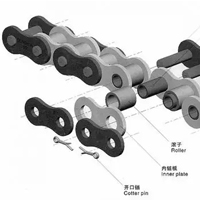

The chain runs smoothly and fast as there’s less drag.

The film is uniform, with no powder mold release.

Compared with other forms of hot air circulation, saves energy consumption by almost 20%.

Gear is specially designed for the latex glove making machine, the whole part has been heat treated, has chemical corrosion resistance, and high durability, and is equipped with a chain automatic load-bearing system.

Product qualification rate reached more than 98%.Protein content is lower than 120 micrograms per gram.

Solving many complex problems such as difficult synchronization, complex maintenance, and more failures.

This process can fully stir the latex without foaming phenomenon, and meet the requirements of long-term normal operation of a Latex gloves machine.

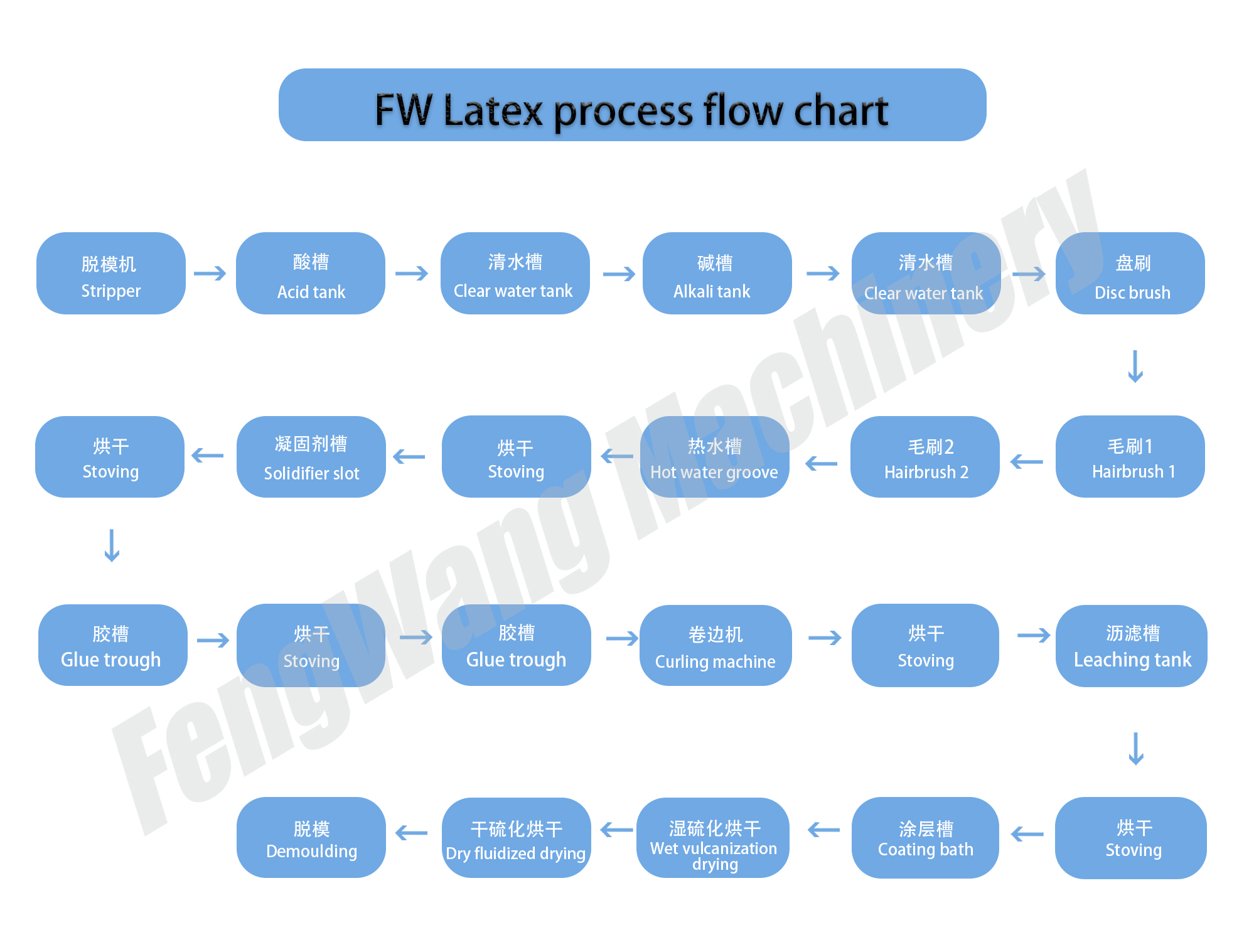

Latex Glove Production Line Process Flow

Fengwang not only provides drawings for your latex gloves manufacturing machine design, installation, post-commissioning, after-sales maintenance services, but also provides latex glove manufacturing process guidance, which is a very important step in the latex glove manufacturing.

Resource to Customize Latex Glove Production Line?

There is no uniform standard equipment for latex glove machine, which requires a specific latex glove manufacturing business plan according to factors such as temperature and humidity in the production area, site area and output.And continuous maintenance and upgrade of the latex glove production line.

Does Your Latex Glove Plant Face These Problems?

- Want to set up a disposable latex gloves production line, but do not understand the latex glove manufacturing process and line layout?

- Is the speed of the production line not up to par?

- Want to change the latex glove making machine to a nitrile glove line?

- Want to improve the current situation of aging hand gloves manufacturing machines?

- The glove formers cannot be cleaned?

Fengwang Custom Latex Glove Production Line Serious

Fengwang can do the whole latex glove production line, also a single latex machine in the production line, including stacking machines, stripping machines, packaging machines, beading machines, glove formers, glove formers holders, intelligent refueling machines, etc. Fengwang provides you with the ultimate solution when you raise the problems you encounter in the production of latex gloves.

Choose Fengwang Latex Gloves Production Line

Fengwang latex glove making machine Over the past twenty years, the automation requirements have increased, and the workshop layout is designed according to customer requirements.

The end customers of Fengwang latex gloves manufacturing machines are disposable glove factories worldwide. We understand the needs of glove manufacturing factories and make machines that satisfy them.

Customers who have worked with us for over 10 years trust us because we always deliver on time with reliable quality assurance.Goods must pass strict quality inspection before they leave factory. Customers decide whether to sign for goods after the initial and final acceptance.

Fengwang is always able to show customers the latest technology in the automatic glove machinery industry. And can save latex gloves manufacturing plant costs for customers to establish long-term cooperation.

About Latex Gloves Production Line

- Parameter Table

|

SINGLE MODEL

|

||||

|

MODEL

|

MACHINE SIZE

|

CAPACITY

(pcs/hr) |

Heat consumption (10,000 kcal/hr)

|

POWER(KW)

|

|

FWSM60

|

60*2.2*9m

|

3,360-4,368

|

40

|

178

|

|

FWSM80

|

80*2.2*9m

|

7,440-9,672

|

90

|

185

|

|

FWSM100

|

100*2.2*9m

|

9,480-12,324

|

115

|

210

|

|

FWSM120

|

120*2.2*9m

|

12,240-15,912

|

150

|

240

|

|

FWSM140

|

140*2.2*9m

|

14,400-18,720

|

180

|

290

|

|

FWSM160

|

160*2.2*9m

|

16200-21,060

|

200

|

320

|

|

FWSM180

|

180*2.2*9m

|

18,600-24,180

|

230

|

360

|

|

DOUBLE MODEL

|

||||

|

MODEL

|

MACHINE SIZE

|

CAPACITY

(pcs/hr) |

Heat consumption (10,000 kcal/hr)

|

POWER(KW)

|

|

FWDM80

|

80*2.4*12m

|

13,200-17,160

|

160

|

195

|

|

FWDM100

|

100*2.4*12m

|

18,000-23,400

|

220

|

223

|

|

FWDM120

|

120*2.4*12m

|

22,800-29,640

|

280

|

250

|

|

FWDM140

|

140*2.4*12m

|

24,000-31,200

|

290

|

300

|

|

FWDM160

|

160*2.4*13m

|

31,200-40,560

|

380

|

330

|

|

FWDM180

|

180*2.4*13m

|

38,400-49,920

|

460

|

380

|

|

FWDM200

|

200*2.4*13m

|

43,200-56,160

|

520

|

400

|

|

The above specifications are for reference,Production lines can be customized according to your requirements.

|

||||

Latex Glove Production Line

The structure of a latex glove production line includes multiple machines, each with specific processes to ensure efficient, continuous, and automated production from raw materials to finished products. Below are the main components of a latex glove production line.

Raw Material Preparation System. It is composed of latex storage tanks, coagulant tanks, batching and mixing equipment, and a filtration system. Its primary function is to store and prepare latex raw materials and other chemical additives.

Mold Cleaning and Pre-treatment System. Consists of a glove former cleaning system, coagulant dipping tanks, and drying devices (for drying the coagulant). It is mainly used to clean the molds and apply the coagulant, preparing them for the subsequent latex dipping process.

Latex Dipping System. Typically includes a latex dipping tank, a rotating or chain-driven mechanism (to ensure even dipping of the molds), and a latex thickness control device. Its main function is to dip the molds into the latex to form a uniform glove film.

Pre-drying and Beading System. Comprises a pre-drying tunnel and a beading device (mechanical or pneumatic). Its primary function is to pre-dry the dipped gloves and form the beaded edge structure of the gloves.

Vulcanization System. Consists of a vulcanization oven and a temperature control system. Its main function is to cross-link and cure the latex through high-temperature vulcanization, enhancing the strength and elasticity of the gloves.

Washing and Rinsing System. Includes washing tanks, rinsing tanks, and a water circulation system. Its primary function is to remove residual chemicals and impurities from the surface of the gloves.

Drying System. Composed of a drying tunnel and a hot air circulation system. Its main function is to thoroughly dry the gloves, ensuring no moisture remains in the finished product.

Stripping System. Consists of a demolding device (mechanical claws or pneumatic devices) and a glove blowing device. Its primary function is to peel the gloves off the molds.

Packaging System. Includes an automatic counting device, a packaging machine, and a labeling machine. Its main function is to pack the qualified gloves in specific quantities.

Control System. Composed of a PLC (Programmable Logic Controller), HMI (Human-Machine Interface), sensors, and a feedback system. Its primary function is to monitor and regulate the operation of the entire production line.

Auxiliary Equipment. Includes a compressed air system, a water treatment system, and an exhaust gas treatment system (to meet environmental requirements). Its main function is to support the normal operation of the production line.

In summary, a latex glove manufacturing line is a highly integrated intelligent production system that involves the entire process from raw material handling to finished product packaging. With years of experience and technological improvements, Fengwang Tech’s latex glove dipping line is known for its efficiency, intelligence, and full automation, making it highly popular among glove manufacturers.