Latex gloves are disposable protective gloves commonly used in life or the medical field. They are characterized by waterproof, non-slip, acid and alkali resistance, wear resistance, and strong elasticity. These properties of latex gloves make it suitable for the following areas:

First of all, in the food processing industry, with the improvement of environmental hygiene requirements, the demand for disposable latex gloves will continue to increase to ensure the safety of users and the purity of food.

Second, in Electronic industry manufacturing, latex gloves due to their good tensile, and close to the skin, are suitable for the electronic industry manufacturing industry, and hand skin protection.

Finally, the precision electronics and medical industries tend to choose purified disposable latex gloves. After washing with water, these gloves are chlorine-cleaned again to ensure that their cleanliness reaches 100 or 1000 levels and meets the requirements of high-cleanliness working environments.

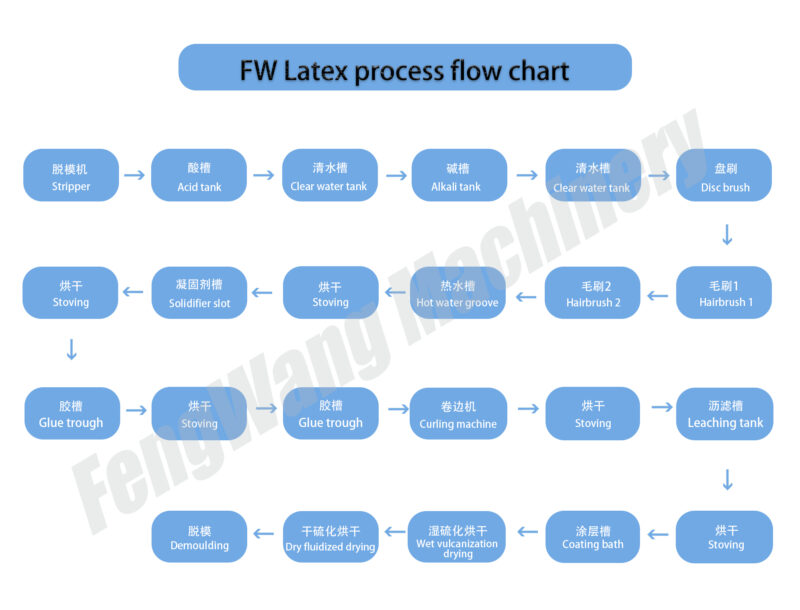

Latex Gloves Production Process

In the latex gloves manufacturing machinery industry, Fengwang has 20 years of experience and is a professional latex gloves machine manufacturer. We have served more than 1000+ customers. Glove manufacturing services include disposable latex glove making machines, latex inspection glove making machines, latex surgical glove making machines, household latex glove making machines, etc. The following is the production process of disposable latex gloves.

1. Prepare raw materials for gloves: raw materials for latex gloves are obtained by precipitation and filtration of 100% natural latex liquid.

2. Adding additives: Chemical additives need to be added after obtaining the latex stock solution to improve the performance and durability of latex gloves. Commonly used auxiliaries include vulcanizing agents, matting agents, and so on.

3. Dipping: The glove former of the production line is immersed in the latex raw material tank. The speed of the latex glove production line determines the thickness of the coated glove and whether the glove surface is uniform to ensure that the quality of the glove meets the standard.

4. Vulcanization: Put the glove-coated mold into the vulcanization furnace for vulcanization. Vulcanization is the process of reacting the natural glue in the latex with the added vulcanizing agent to make the latex form a solid glove. The temperature and time need to be controlled during vulcanization to ensure the strength and elasticity of the gloves.

5. Stripping: At this time, the glove has been preliminarily formed and begins to enter the stripping process, the role of Fengwang glove stripping machine is to take off the glove half on the hand mold, and then enter the next process. After the mold is removed, the glove retains the shape and size of the mold.

6. Counting and packaging: When the gloves are half taken off, they will pass through the counting machine, and the counting machine will take off the gloves and stack them neatly according to a certain number. At this time, the gloves need to be packed and waiting for loading and transportation.

In summary, the Latex gloves production process mainly includes preparing raw materials, adding chemical additives, dipping, vulcanization, stripping, counting, and packaging.

Li Jianqiang, general manager of Fengwang, reminded us that the entire production process of latex gloves needs to control the quality of raw materials, production process details, timely maintenance of machines, etc., to ensure the quality standards and safety performance of latex gloves.

Watertight Test System

When the finished gloves are produced, they are tested in different ways according to different use scenarios. Fengwang’s watertight test system is new equipment for professional glove pinhole testing. First, a part of the latex gloves is extracted from the finished gloves for a watertight test experiment. The machine fills the gloves with water and records the leakage of the test.

The test results determine the classification of gloves, and medical-grade latex gloves may undergo more rigorous testing. This strict production of gloves according to the standard to maintain the stability of the market order, will not be shoddy, or fake so that latex glove manufacturers can achieve real conscience production.

Fengwang Manufacturing Latex Gloves Production Line Specifications

|

SINGLE MODEL

|

||||

|

MODEL

|

MACHINE SIZE

|

CAPACITY

(pcs/hr) |

Heat consumption (10,000 kcal/hr)

|

POWER(KW)

|

|

FWSM60

|

60*2.2*9m

|

3,360-4,368

|

40

|

178

|

|

FWSM80

|

80*2.2*9m

|

7,440-9,672

|

90

|

185

|

|

FWSM100

|

100*2.2*9m

|

9,480-12,324

|

115

|

210

|

|

FWSM120

|

120*2.2*9m

|

12,240-15,912

|

150

|

240

|

|

FWSM140

|

140*2.2*9m

|

14,400-18,720

|

180

|

290

|

|

FWSM160

|

160*2.2*9m

|

16200-21,060

|

200

|

320

|

|

FWSM180

|

180*2.2*9m

|

18,600-24,180

|

230

|

360

|

|

DOUBLE MODEL

|

||||

|

MODEL

|

MACHINE SIZE

|

CAPACITY

(pcs/hr) |

Heat consumption (10,000 kcal/hr)

|

POWER(KW)

|

|

FWDM80

|

80*2.4*12m

|

13,200-17,160

|

160

|

195

|

|

FWDM100

|

100*2.4*12m

|

18,000-23,400

|

220

|

223

|

|

FWDM120

|

120*2.4*12m

|

22,800-29,640

|

280

|

250

|

|

FWDM140

|

140*2.4*12m

|

24,000-31,200

|

290

|

300

|

|

FWDM160

|

160*2.4*13m

|

31,200-40,560

|

380

|

330

|

|

FWDM180

|

180*2.4*13m

|

38,400-49,920

|

460

|

380

|

|

FWDM200

|

200*2.4*13m

|

43,200-56,160

|

520

|

400

|

|

The above specifications are for reference, Production lines can be customized according to your requirements.

|

||||

Latex Gloves Manufacturing Plant Cost

As can be seen from the specifications of the latex glove manufacturing machine above, the latex glove production line is divided into single mode and double mode, the length of the single mode is 60-180 meters, the minimum output is 3,360pcs/hr, the length of the double mode is 80-200 meters, the maximum output is 56,160pcs/hr. Therefore, different specifications for latex glove manufacturing plant costs are different, so want to know the latex glove manufacturing machine price, please contact us for an accurate quote.