Fengwang Counting Machine Order

At the end of 2024, we received an order from a customer in the United States. Because the customer was in a hurry to order, he chose air transportation, and the order quantity was just within the range of our inventory. After determining the payment method, price, and quantity, we will pack and ship the machine for the customer in the shortest possible time to ensure that it is delivered to the customer on time.

Basic Principle of Glove Counting Machine

The automatic glove counting machine is consistent with the speed of the glove production line. When the glove is produced after the stripping machine, it is half taken off, and then the hand model passes the counting machine. The glove is completely taken off and stacked neatly according to the number set in advance.

Fengwang automatic counting machine can automatically grasp the gloves on the upper half of the hand model, only one glove is coded to facilitate counting, and the speed of the code glove is consistent with the speed of the glove production line. How does it work?

How Automatic Glove Counting Machine Work Video

1. When the half-removed glove formers pass the glove stacking machine, the manipulator clamps begin to grab the gloves and stack them neatly. The sensor count increases by 1 for each glove that is grabbed.

2. In general, every 100 gloves are stacked into a stack, and when the manipulator clamp grabs 100 times, the folded and counted gloves on the taking table are automatically transferred to the worker by the conveyor belt for the next packaging process. The above workflow is controlled by PLC microcomputer.

The overall operation is almost error-free, but there are exceptions. For example, the manipulator clamp did not catch the gloves stacked on the counting machine’s conveyor belt. The touch screen does not increase the number of gloves. The actual number of gloves on the touch screen is the number of gloves that the counting machine grabs.

Glove Counting Machine Advantages

- Use PLC program with automatic and manual control in two modes, and the operation is simple and easy to understand.

- Relatively small in size and does not take up much space.

- Stable counting: 80-150 pieces/box can be arbitrarily set if the speed allows, and the set number can be reached ±1.

- The grasping speed and counting speed of the counting machine can be designed according to customer needs.

Type I can adapt to the speed of 5 gloves at a time: 160 gloves/minute. Type II can adapt to the speed of 6 gloves at a time: 200 gloves/minute

- The manipulator clamp grabs the gloves, which has a high level of safety protection for the gloves and will not scratch the gloves.

- Low maintenance cost, saving time and effort.

- Glove counting machine noise <40dB, energy saving, and environmental protection.

- It solves the problem of high error rate and high cost of traditional manual counting gloves, improves the production efficiency of gloves, and reduces the cost of glove manufacturers.

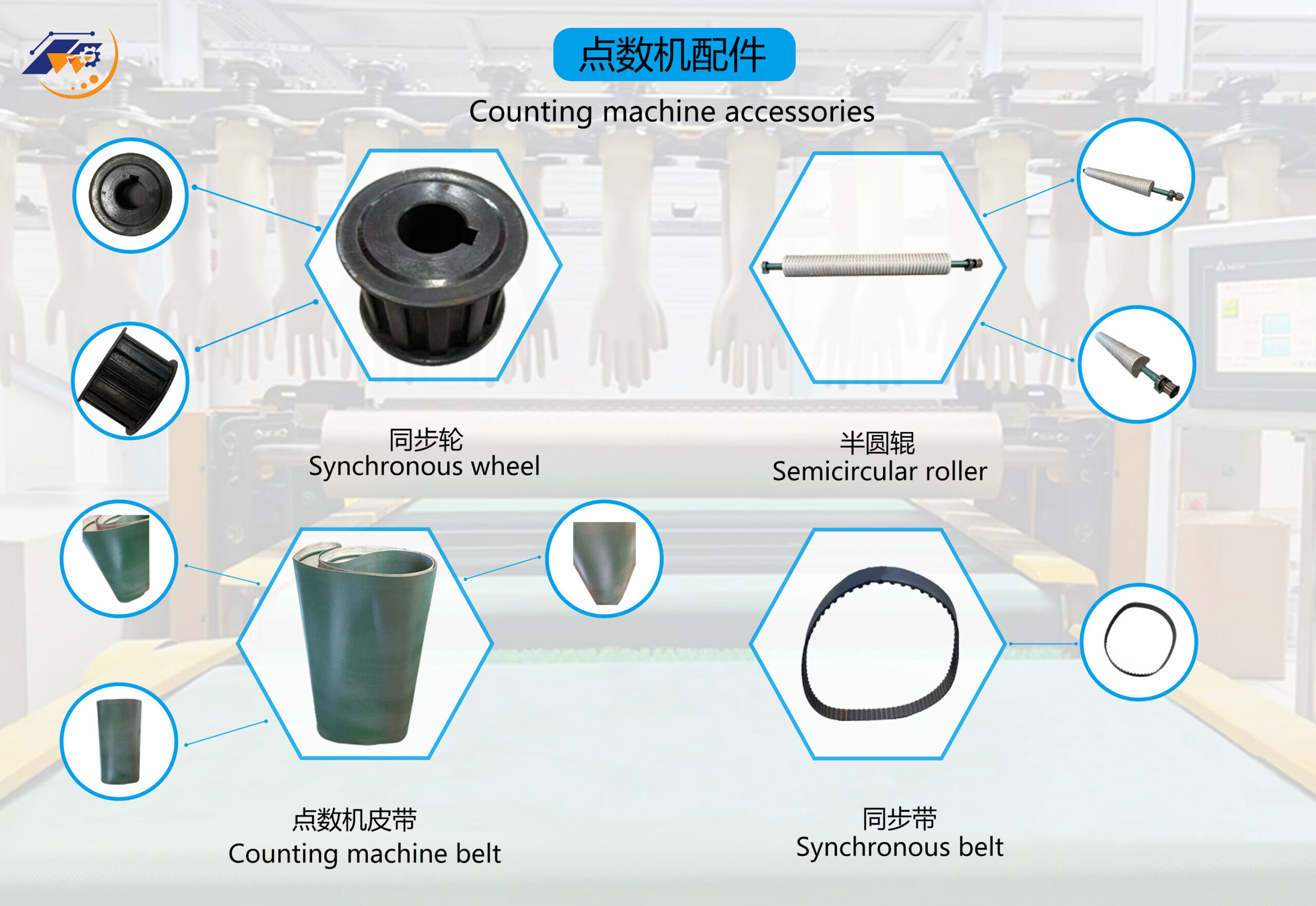

Glove Counting Machine Structure

The electrical part is mainly composed of PLC, touch screen, servo motor, and photoelectric sensor.

Each time grabs glove specifications: 4, 5, 6 (customizable)

About Glove Stacking

In general, gloves are neatly stacked on the conveyor belt of the counting machine, but there are exceptions. When the following phenomena occur, it is necessary to maintain the counting machine in time.

1. When the glove is completely removed, it is curled, that is, the glove is not flat on the belt. There are two reasons for this:

The speed of the half-circle roll is too fast, and the response speed of the positive and negative belt is slow when the glove is dropped, so the speed of the half-circle roll is reduced.

The positive and negative belts respond too quickly, resulting in the conveyor belt entering distance and backward distance can not meet the length of the glove. We should increase the delay time for conveyor takeovers.

2. The front or back of the glove is not in place:

First of all, be sure to confirm that the forward distance and backward distance Settings in the conveyor belt are consistent.

Secondly, observe the height of the semicircular roll and the positive and negative belt.

Then see if the length of the gloves taken off by the stripping machine is the same. If the height of the semicircle does not fit the height of the positive and negative band, we need to adjust the height of the positive and negative band, the initial height of the positive and negative band, and the height of the close switch through the upper limit bit.