Raw Materials for Disposable Gloves

Because disposable gloves use different raw materials, the process of making gloves will be slightly different.

Four main materials are used to make disposable gloves: nitrile butadiene rubber, natural latex, polyvinyl chloride, and polyethylene.

Latex is the oldest and most familiar raw material for glove making. The increased use of latex gloves, especially during the AIDS crisis of the 1980s, raised awareness of latex allergies, leading to the introduction of vinyl and nitrile gloves in the mid-1990s. Both materials do not contain plant proteins that cause allergic reactions, and while they replace latex in many use cases, they are still irreplaceable for some uses.

Where Nitrile and Vinyl Come From?

The process of making nitrile and vinyl gloves is similar. Nitrile butadiene rubber (NBR), used in nitrile gloves, is a copolymer, a substance made of molecules bonded together. In the case of nitrile rubber, the two parts are butadiene and acrylonitrile, which chemists combine using a process called copolymerization.

These molecules provide special advantages for gloves: acrylonitrile enhances chemical resistance, while butadiene enhances flexibility and tear resistance.

Polyvinyl chloride (PVC) must be produced in polymer production facilities by polymerization of vinyl chloride monomers. Then, the raw PVC material receives a plasticizer to make it soft and pliable; Otherwise, PVC will be rigid as it is used to form pipes. It is then sent to the glove manufacturing plant.

Once the synthetic materials are ready, they are used in the glove production process. With a few exception-mostly involving washing and chlorinating to remove latex proteins-the process is essentially the same as the steps used to make latex gloves.

The final step in this glove manufacturing process is the glove inspection, which is then boxed and shipped to the customer.

Polyethylene is the most affordable glove material and is primarily used in the food service industry.

It is a polymer made from ethylene and thermoplastics, which form various shapes when cooled from liquid to solid.

Two sheets of polyethylene are sewn and sealed with heat to make disposable gloves. Polyethylene gloves are a suitable choice for food service tasks with liquids.

On the Disposable Glove Production Line

In glove production, ceramic or aluminum glove formers are first cleaned with hot water and chlorine to remove all residue.

Next, the glove suspended on a continuously moving chain is immersed in a mixture of calcium nitrate solution and calcium carbonate – nitrate is a coagulant, and calcium carbonate helps release the glove from the glove.

After drying, the glove former is immersed in the latex mixture, and the length of immersion determines the thickness of the glove.

The freshly glove formers are then leached in a mixture of hot water and chlorine, which removes residual latex proteins and chemicals to help reduce the severity of allergic reactions to latex.

The gloves are then dried and cured, and then vulcanized to transform the gloves into elastic gloves.

Fengwang-Your Trusted Partner

Fengwang’s (nitrile, latex, PVC) glove production line adopts the most advanced modern factory equipment layout scheme, high-quality power and transmission system, the production line has low running resistance and runs smoothly during continuous high-speed production. In addition, the optimized production process ensures that the disposable gloves produced by the glove manufacturer have a high yield and excellent quality.

Fengwang provides production line design, whole plant planning, equipment manufacturing (installation), operation training, process formula, auxiliary equipment, spare parts procurement and other one-stop services, so that you save worry and effort!

Buy Fengwang glove production equipment, enjoy professional after-sales service, 24 hours remote technical support.Ready to arrive if repairs are needed!

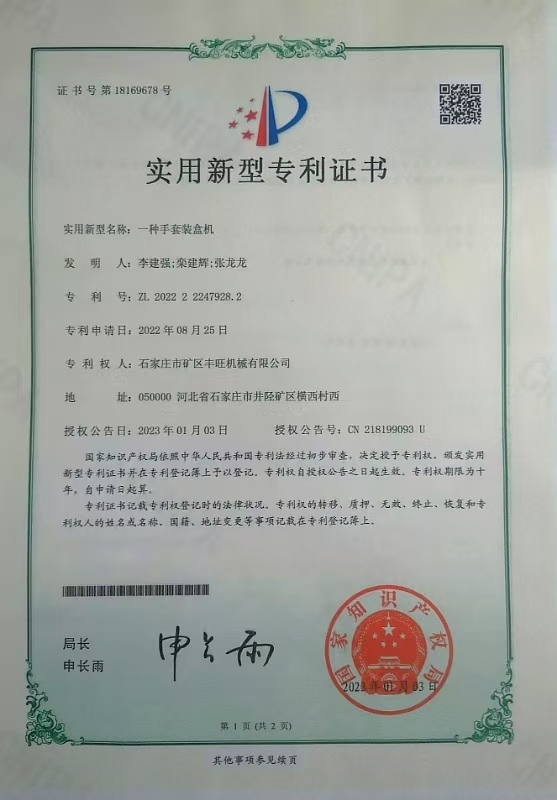

Patent Certificate of Fengwang

Fengwang has a number of national invention and utility model patents, won a number of honorary titles such as high-tech enterprises, professional and special new enterprises, science and technology enterprises, and passed the ISO9001 international standard quality management system certification. The company was officially listed in January 2024, injecting new impetus and vitality into the company’s development.

The latest utility model patent discloses a hand box machine, also called automatic glove packaging machine. This packaging machine is an automatic technology product that boxes and seals gloves in the production line of disposable gloves. The product mainly includes three links: packing , box forming, and sealing. The packing is to send the gloves to the box; The box forming is to realize the forming of the box; The sealing is to seal the box. The automatic glove packing machine needs to use a non-stick sealing method, which can be selected according to the specific requirements of customers. The packaging capacity of the equipment is 5-7 boxes/minute and can be used on the production line or in the packaging room.