What Is The Auto Glove Stacking Machine?

A disposable glove stacking machine also called a glove layering system is a fully automatic gloves production machine. Auto stacking machines for gloves can be in the gloves production line in the high-speed operation and the gloves are accurately sorted and stacked according to the preset number of gloves.Not only convenient packaging but also ensuring the number of gloves in the glove box.

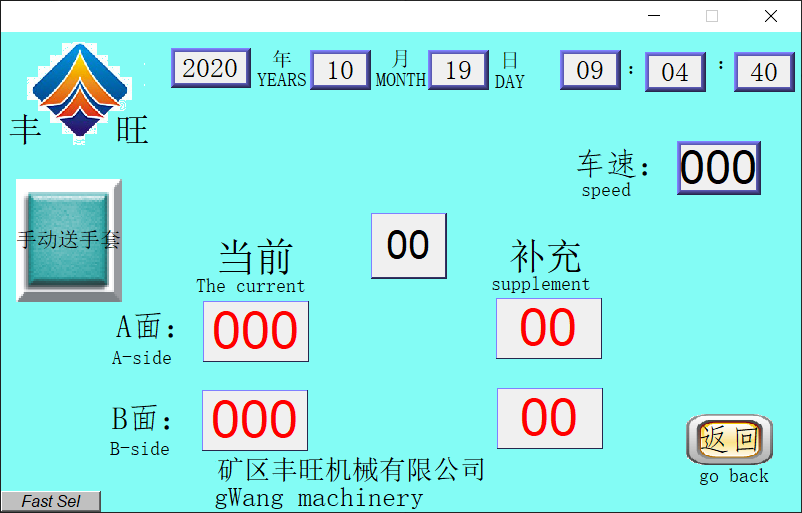

Fengwang Auto Stacking Machine for Glove

Advantages by Auto Stacking Machine for Glove

Saves production time and costs, easier to produce gloves quickly.

Make sure the number of gloves in each pile is consistent and stacked neatly.

It completely replaces the manual counting and manual stacking of gloves.

Our technician knows the machine inside out with many years experience.

How Does A Glove Stacking Machine Work?

In the disposable glove production line, the glove stacking machine is also called the glove layering system, which can take off the gloves that stay on the fingertips of the glove formers and automatically stack them neatly according to the specified number.Watch the video.

Recent Hand Gloves Manufacturing Machine Order

The sprocket Wheel is the gut of the entire glove production line, without which the glove production line cannot be rotated.

The Material in the Material Tank determines the glove manufacturer to make what kind of glove.

At present, there are many gloves stacking machines in stock in the warehouse, and each one can be sent out at any time.

The Half Round Roller Shaft is the main part of the glove stacker. It is made of rubber.

- Parameter Table

| Specification | Power | Adaptive speed | Voltage |

| 1350*1200*700mm | 3KW | 80-160pieces/minute | 220V |

About the Neat Problem of Disposable Gloves

1.Gloves are rolled or bent after being taken off, that is, the gloves are not laid flat on the belt. There are two reasons for this situation:

✪The speed of the half-round stick is too fast, when the glove falls, The positive and negative belt response speed is slow, so reduce the speed of the semicircle roll.

✪The positive and negative belt responds too quickly, resulting in the conveyor belt entering distance and retreat distance can not meet the length of the glove.We should increase the conveyor belt took over time delay.

2.Gloves are out of position in front or back:

First of all, be sure to confirm the Distance Setting in the conveyor belt forward distance and backward distance must be consistent.

Secondly, observe the height of the semicircle roll and the positive and negative belt, And then see whether the length of the gloves taken off by the stripping machine is basically the same. If the height of the semicircle roll and positive and negative belt is not suitable, we need to adjust the height of the positive and negative belt, the initial height of the positive and negative belt, the height of proximity switch through the upper limit bit.The height of each time the gloves are removed is adjusted by the automatic drop distance in the distance setting.