Automatic Disposable Glove Production Line Sprocket

The function of the automatic disposable glove production line sprocket is to adjust the speed of the hand mold running on the production line, so that the uniformity of the rubber material on the hand mold is adjusted, so that the gloves produced are more in line with the requirements of the business and the products are optimized. In addition, the sprocket improves the quality of the production line and reduces manual operation, which reduces the cost of the auto glove production line.

How Does A Sprocket Work?

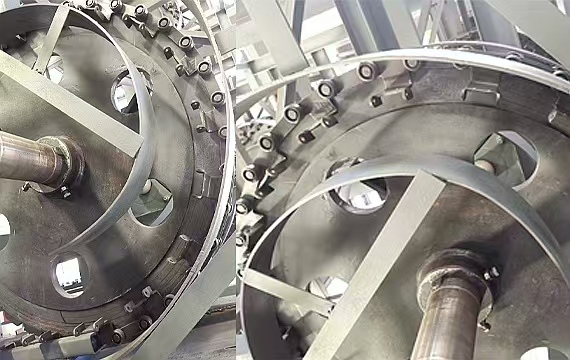

How do Sprockets work in the glove production line, please open the video on the right.Then you can see how sprockets play their role in the glove production line.

About Fengwang Sprockets and Chains

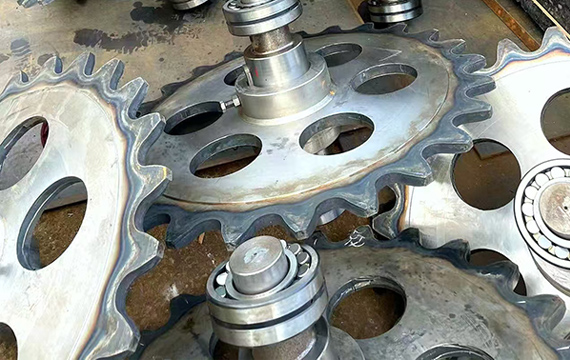

Materials: Usually, due to the continuous production of the production line and the mutual wear between the machinery, the glove production line sprockets are made of high-strength materials such as steel or stainless steel.

The material is made of stainless steel in the form of a combination of pins and hexagonal balls, making the hand drive more portable and flexible, Suitable for making a certain weight or larger specifications of the model of gloves.

Bearings: Two sizes of bearings are used to ensure smooth operation of the chain. Our bearings use special greases to prevent oil spills after high temperatures.

The glove production line sprocket installation process is carefully shielded to ensure that there is no dirt and glue during operation. Sprockets are equipped with a specially designed gear and chain system using high-strength chains, special steel chain materials to ensure high durability.

The chain is the life of the glove production line, each process of the production line is driven by the chain, and connected to the entire process, different production lines use different drive chains, we use 100mm pitch chain relative to all kinds of tracks, the main purpose is to reduce wear in the transmission process.

The noise of the chain during operation is small and the speed is stable. And gravity is used to tighten the system to ensure that the chain is tight at all times so that the gloves flow seamlessly on the production line.

The structure of the conveyor chain of the disposable glove machine is characterized by a single row of chain rings, relying on the center to carry the load. This design helps distribute the force acting on the drive ring evenly to the chain plates on both sides, reducing wear and noise.

Lubrication: Lubrication is very important for the chain and can at least double its service life. Choosing the right grease and lubrication method is very important.

We are committed to producing high performance latex/nitrile/PVC glove production lines, improving the efficiency and stability of glove production lines, while striving to reduce costs for users.

Features of Disposable Glove Conveyor Chain

- It is suitable for plastic, rubber and other industries to maintain high stability, noise reduction, wear resistance requirements of synchronous conveying equipment.

- Simple and reliable structure, easy maintenance, low operating cost.

- Stainless steel chain and frame parts in different colors can be customized according to customer requirements.