Application of Nitrile Gloves

Medical industry: Nitrile gloves are widely used in medical scenarios due to their good comfort, chemical resistance, and puncture resistance. They can effectively prevent viruses and bacteria from entering the body, protecting the safety of medical staff and patients. Nitrile gloves are comfortable to wear and close to the finger, suitable for more delicate operations.

Industrial manufacturing industry: in food processing, machinery manufacturing, and other industries, nitrile gloves provide effective protection for people’s hands, with the increasing requirements of food environmental hygiene standards, people are required to wear gloves in food processing operations, so nitrile gloves in the field of food hygiene processing demand is increasing.

Home cleaning: When cleaning the home, the chemicals in the detergent can cause damage to the skin on the hand, and nitrile gloves can prevent chemical contact with the skin, so that the skin is protected from damage. While cleaning, nitrile gloves prevent dirty things from entering the skin and reduce skin damage.

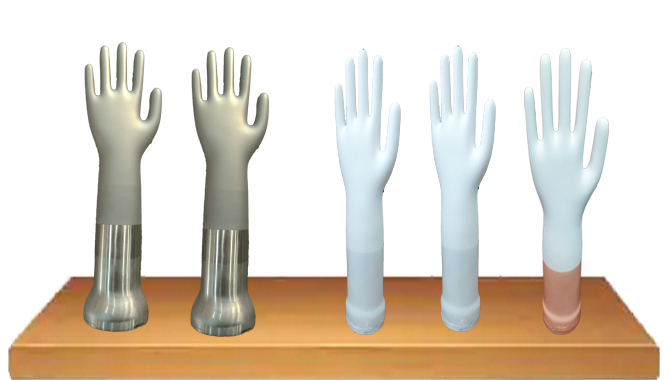

Features of Stainless Steel Glove Former for Nitrile Gloves

The stainless steel glove former for nitrile gloves is made of 316 stainless steel (food grade). The surface specifications are finger hemp and general hemp, the mold can evenly conduct heat, and the thickness is 1.5MM.

1. Good thermal conductivity: The stainless steel glove former is made of 316, and 304 stainless steel, and its thermal conductivity effect is 4 times that of ceramic, saving more than 20% of energy consumption, and greatly improving production efficiency.

2. Fine process: Stainless steel hand mold with uniform thickness inside and outside (1.5MM), weight of 470g, simple replacement, easy operation, thereby helping to improve the production efficiency and quality of the glove production line.

3. Corrosion resistance: Glove former is characterized by acid and alkali resistance, corrosion resistance, long service life, and no perforation leakage phenomenon.

4. Easy to clean: Stainless steel glove former easy to clean, with no need to clean with acid and alkali water, only butyl ketone scrub, environmental protection, and cost saving.

Why do Nitrile Gloves Have Pinholes?

Erroneous operations in the production process, such as improper control of temperature and pressure, lead to defects, namely pinholes when the glove former is formed.

The quality problems of the raw materials of gloves, such as debris or fine particles in the raw materials, cause pinholes in the glove forming process.

Thermal Shock Resistance of Ceramic Hand Models

Ceramic hand mold is widely used in nitrile glove production lines, but ceramic hand mold has its disadvantages, namely poor thermal shock resistance. During the long-term operation of the nitrile glove production line, the ceramic hand is under the action of cyclic thermal shock, the surface cracks, spalling, and eventually cracks or deteriorates, and the resistance to such damage is called thermal shock damage resistance. At present, people have not yet given clear indicators on how to reflect the thermal shock resistance of ceramic products more scientifically and essentially, so how to improve the thermal shock resistance of nitrile hand models is still an important research topic that people are chasing.