The Difference Between Nitrile and Latex Gloves

Disposable nitrile and latex gloves are widely used in industrial fields, medical fields, daily life, etc., but there are many differences between them. The following section introduces the three aspects of the difference between nitrile and latex gloves.

1. Gloves are made of different materials

The raw material of latex gloves is natural latex, and nitrile gloves are processed from nitrile rubber synthetic materials.

2. The characteristics of gloves are different

Latex gloves: made of natural latex raw materials, latex gloves have wear resistance and puncture resistance; Resistant to acid, alkali, grease, fuel, and a variety of solvents; Have a wide range of chemical resistance, and proof effect is good; Latex gloves feature a unique fingertip texture design that greatly enhances grip strength and effectively prevents slippage.

Nitrile gloves: Nitrile inspection gloves can be worn on both left and right hands, are made of chemical synthetic raw materials, do not contain protein, and effectively avoid the protein allergy problem of latex gloves; The main properties are puncture resistance, oil resistance, and solvent resistance; Hemp surface treatment, to avoid the use of the appliance to slip; The high tensile strength avoids tearing when wearing, but the tensile property is slightly worse than that of latex gloves, and nitrile gloves are easy to wear after powder free treatment.

3. Different uses

Latex gloves are used in industrial, medical, beauty, and other industries, suitable for automobile manufacturing, battery manufacturing, FRP industry, aircraft assembly, aerospace field, environmental cleaning and cleaning, and other fields.

Nitrile gloves are mainly used in medical, health, beauty salons, food processing, factory repair, and other operating industries.

Briefly Describe the Latex Gloves Production Line Flow

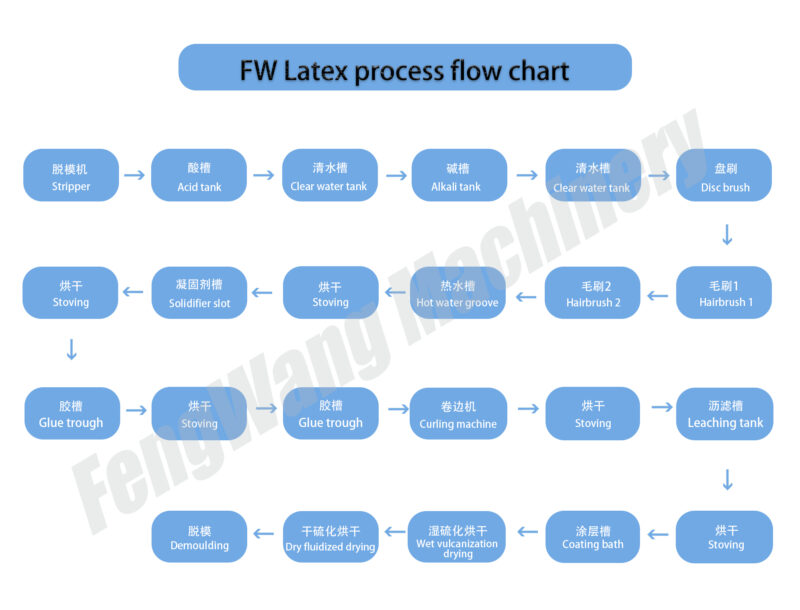

Fengwang latex gloves production line consists of four main processes: pre-vulcanization, latex dipping, finishing, inspection, and packaging.

The latex gloves dipping process includes cleaning, dipping, beading, drying, stripping, and other production units connected into a continuous cycle operation of the equipment. This line can produce latex and nitrile gloves of different raw materials. The production capacity of the production line ranges from 3,360 pieces/hour to 56,160 pieces/hour.

Latex Gloves Production Line Specifications

|

SINGLE MODEL

|

||||

|

MODEL

|

MACHINE SIZE

|

CAPACITY

(pcs/hr) |

Heat consumption (10,000 kcal/hr)

|

POWER(KW)

|

|

FWSM60

|

60*2.2*9m

|

3,360-4,368

|

40

|

178

|

|

FWSM80

|

80*2.2*9m

|

7,440-9,672

|

90

|

185

|

|

FWSM100

|

100*2.2*9m

|

9,480-12,324

|

115

|

210

|

|

FWSM120

|

120*2.2*9m

|

12,240-15,912

|

150

|

240

|

|

FWSM140

|

140*2.2*9m

|

14,400-18,720

|

180

|

290

|

|

FWSM160

|

160*2.2*9m

|

16200-21,060

|

200

|

320

|

|

FWSM180

|

180*2.2*9m

|

18,600-24,180

|

230

|

360

|

|

DOUBLE MODEL

|

||||

|

MODEL

|

MACHINE SIZE

|

CAPACITY

(pcs/hr) |

Heat consumption (10,000 kcal/hr)

|

POWER(KW)

|

|

FWDM80

|

80*2.4*12m

|

13,200-17,160

|

160

|

195

|

|

FWDM100

|

100*2.4*12m

|

18,000-23,400

|

220

|

223

|

|

FWDM120

|

120*2.4*12m

|

22,800-29,640

|

280

|

250

|

|

FWDM140

|

140*2.4*12m

|

24,000-31,200

|

290

|

300

|

|

FWDM160

|

160*2.4*13m

|

31,200-40,560

|

380

|

330

|

|

FWDM180

|

180*2.4*13m

|

38,400-49,920

|

460

|

380

|

|

FWDM200

|

200*2.4*13m

|

43,200-56,160

|

520

|

400

|

|

The above specifications are for reference, Production lines can be customized according to your requirements.

|

||||

What Is a Latex Glove Making Machine

The latex glove making machine produced by Fengwang has been unanimously recognized by domestic and foreign customers for many years, and is famous for high production efficiency, perfect after-sales service, low failure rate, and the production of better quality gloves. So what is a fully automatic latex glove making machine?

The installation of disposable latex gloves equipment mainly includes four parts:

1. Batching equipment, including mixer, filter bucket, vacuum defoaming machine, glue pump;

2. Impregnating equipment, including frame, conveyor chain, impregnating tank, recovery tank, drop tank;

3. Plasticizing furnace;

4. Cooling, lip rolling, powder dusting, de-molding, and de-powder equipment, including cooling group, lip rolling group, powder dusting group, de-molding group, and de-powder group.

Fengwang- Your Advanced Latex Gloves Machine Manufacturer

After more than 20 years of struggle in the disposable glove machine manufacturing industry, Fengwang Tech has developed into one of the most well-known and fastest-growing automatic nitrile latex PVC glove production line manufacturing enterprises in China. Fengwang combines the latest AI technology and robotics innovations to design and manufacture various machines auxiliary equipment and spare parts for the glove production line.

Since its inception, the company has continuously built and improved high-tech infrastructure, equipped with cash production machines and the necessary security measures to support the production of our products in large quantities. In addition, the company offers cost-effective products that are characterized by high efficiency and low maintenance costs.

The continuous improvement of Fengwang technology has ensured the company’s leading position in the disposable glove machine manufacturing market. Not only in China but also in Iran, Turkey, Russia, Malaysia, Thailand, Vietnam, and other overseas markets have gained great recognition.

Become one of the leaders in the field of industrial automation by providing customers with the best products and services.

6 Advantages of Choosing Fengwang Latex Glove Making Machine

Fengwang Technology was established in 1999 in Shijiazhuang, Hebei Province, specializing in nitrile/latex /PVC glove production line manufacturing for more than 20 years. The factory covers an area of more than 20,000 square meters and produces more than 80 sets of nitrile latex PVC glove manufacturing machines per month. With more than 60 experienced workers and 8 mechanical engineering experts, we are ready to provide the perfect solution to any problem.

- Technical capability

Fengwang Technology has the most advanced glove manufacturing industry technology, ready to provide customer service. - Wide range of services

Fengwang Technology offers its customers an impressive range of services to meet the various production technology needs of modern enterprises.Your mechanical projects will always receive timely support. Our team is designed to meet your daily needs such as machine installation, supply of spare parts, commissioning, and maintenance. - Productive capacity

Our company has a strong manufacturing capability, which allows us to undertake projects of different sizes and scope.

- Large customer base

The first-class service provided by Fengwang over the years has earned us an impressive customer base. These include some of the world’s most famous companies including Top Glove and Intco. - A strong team of experts

The company has a strong team of experts, each member of which provides expertise, that is valuable for producing high-quality products with the latest technology. - EXP

With more than 20 years of industry experience, Fengwang is known for providing unmatched products.

Fengwang Latex Glove Manufacturing Machine Case