Fengwang Porcelain Glove Formers

Fengwang porcelain glove formers are for sale.Our porcelain glove mold is used for the production of gloves of various materials, including nitrile, latex, PVC and household gloves. In addition, Fengwang also offers ceramic hand former of surgical gloves, inspection gloves and industrial gloves, etc.

When the glove making machine is running, the glove formers are immersed in the raw material of the glove and the liquid is evenly attached to the porcelain glove mold. After the glove mold hand is dried, the formers go through a series of procedures. Finished gloves are removed from the glove mold hand by a fully automatic glove stripping machine. Therefore, the necessary material properties of the glove mold hand are corrosion resistance, low expansion and thermal shock resistance.

Types of Ceramic Glove Formers

High automation of the production process using modern technology ensures consistent high quality in the manufacturing of ceramic glove formers.

In addition, we offer customized solutions to suit our customers’ needs. These include different texture levels for finger, palm, or whole glove formers, sandblasting or spray applications, and the choice of different coatings. Patterns are available upon request.

Fengwang Dipping Formers Features

Ceramic glove formers made in Fengwang Technology have the following characteristics:

- Thermal shock resistance.

- Resistance against corrosive media.

- Low thermal expansion coefficient.

- White gloves dipping formers.

How to Test and Evaluate Thermal Shock – Corrosion of Glove Former

Fengwang will test and re-evaluate the performance of each ex-factory glove dip mold to ensure the best quality before delivering to the market. Skilled workers with many years of experience will carry out the inspection process.

Professional Supplier of Your Ceramic Glove Former

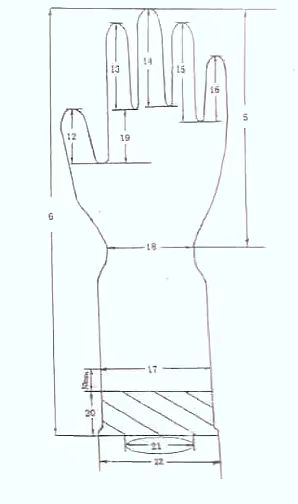

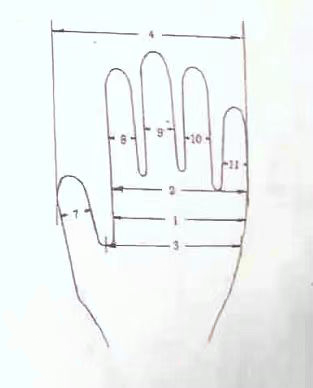

When customizing glove formers, customers need to pay special attention to the size. In the picture below are measurements about our glove formers.

The material thickness recommended by Fengwang Custom glove former is 3.5 mm.

Due to our mechanized production method we are providing a position tolerance of + 0.5 mm for the wall thickness.

Wall thickness can be changed according to customer requirements.

Change may be very necessary for big or small formers. Tolerances of ±0.5mm can be held in all cases.

Fingers are always hollow and well controlled in thickness.

Glove formers preferred standard size bottom slots are 23×56.0 mm or 20.0×56.0 mm. Special sizes are possible.

On formers shown in this catalog used to produce nitrile/latex gloves, there are several options available for size markings. In addition to the standard numerals, sizes may be indicated with words or with letters such as SMALL or S and LARGE or L.

These standard size markings are available from extra small through extra large sizes. In addition, Fengwang also offers customers size markings based upon customer request.

Ceramic Glove Former Custom Guide

Following is the Ceramic glove former size customization solution, click on the professional technician online for details.

| Nitrile Latex Ceramic Glove Former Size Table | ||||||

| Serial number |

Check item | XS | S | M | L | XL |

| 1 | Palm girth | |||||

| 2 | Upper palm width | |||||

| 3 | Lower palm width | |||||

| 4 | Overall width | |||||

| 5 | Palm length | |||||

| 6 | Total length | |||||

| 7 | Thumb girth | |||||

| Thumb root girth | ||||||

| 8 | Index finger girth | |||||

| Index finger root girth | ||||||

| 9 | Middle finger girth | |||||

| Middle finger root girth | ||||||

| 10 | Ring finger girth | |||||

| Ring finger root girth | ||||||

| 11 | Little finger girth | |||||

| Little finger root girth | ||||||

| 12 | Thumb length | |||||

| 13 | Index finger length | |||||

| 14 | Middle finger length | |||||

| 15 | Ring finger length | |||||

| 16 | Little finger length | |||||

| 17 | Cuff diameter | |||||

| Cuff girth | ||||||

| 18 | Wrist width | |||||

| Wrist girth | ||||||

| 19 | From the index finger slit to the base of the thumb |

|||||

| 20 | Glazing height | |||||

| 21 | Aperture | |||||

| 22 | Diameter of base | |||||

| Weight | ||||||

| Enamel color | ||||||

| Error range | ||||||

| Measurement method | The palm girth is measured at 1/2 of the distance between thumb root and index finger root.The finger girth is measured at fingertip 20mm down. The finger root girth is the thumb root up 3mm,and the cuff is measured at fingertips down 260mm | |||||