Professional Nitrile Glove Making Equipment Manufacturer

Fengwang is a nitrile gloves making machine manufacturer. We have been engaged in nitrile Glove machine industry for nearly 20 years, and have served more than 1000 customers, among which well-known customers are Intco,Bluesail,Hongray, etc., Top Glove in Vietnam and some nitrile glove manufacturers in the Middle East.

The production of nitrile gloves is a complex process, and its development has developed from traditional artificial manufacturing to modern fully automatic intelligent mechanization. Fengwang has witnessed the development of the glove manufacturing industry for so many years, and is familiar with every process in the operation of the nitrile glove production machine. We keep up with the trends of The Times, and constantly develop and improve the process of glove manufacturing machinery technology, which facilitates customers to improve the production efficiency of gloves at the same time, simplify the production process, and provide more direct and effective design drawings and the most professional solutions.

Nitrile Gloves Manufacturing Plant Cost

In addition to providing nitrile glove design drawings and solutions, Fengwang also provides training and guidance on the nitrile glove production process. So whether you are setting up a nitrile glove line for the first time, or you want to improve your existing glove line, if you have any ideas or questions about nitrile glove production, you can ask us for help. nitrile gloves manufacturing plant cost is measured according to many factors such as the size of the production line and the output. Fengwang has always focused on providing customers with practical production solutions, real and effective quotations based on good faith, and doing everything possible to satisfy customers. Any information regarding the cost of nitrile gloves manufacturing plant can be asked by a technician online.

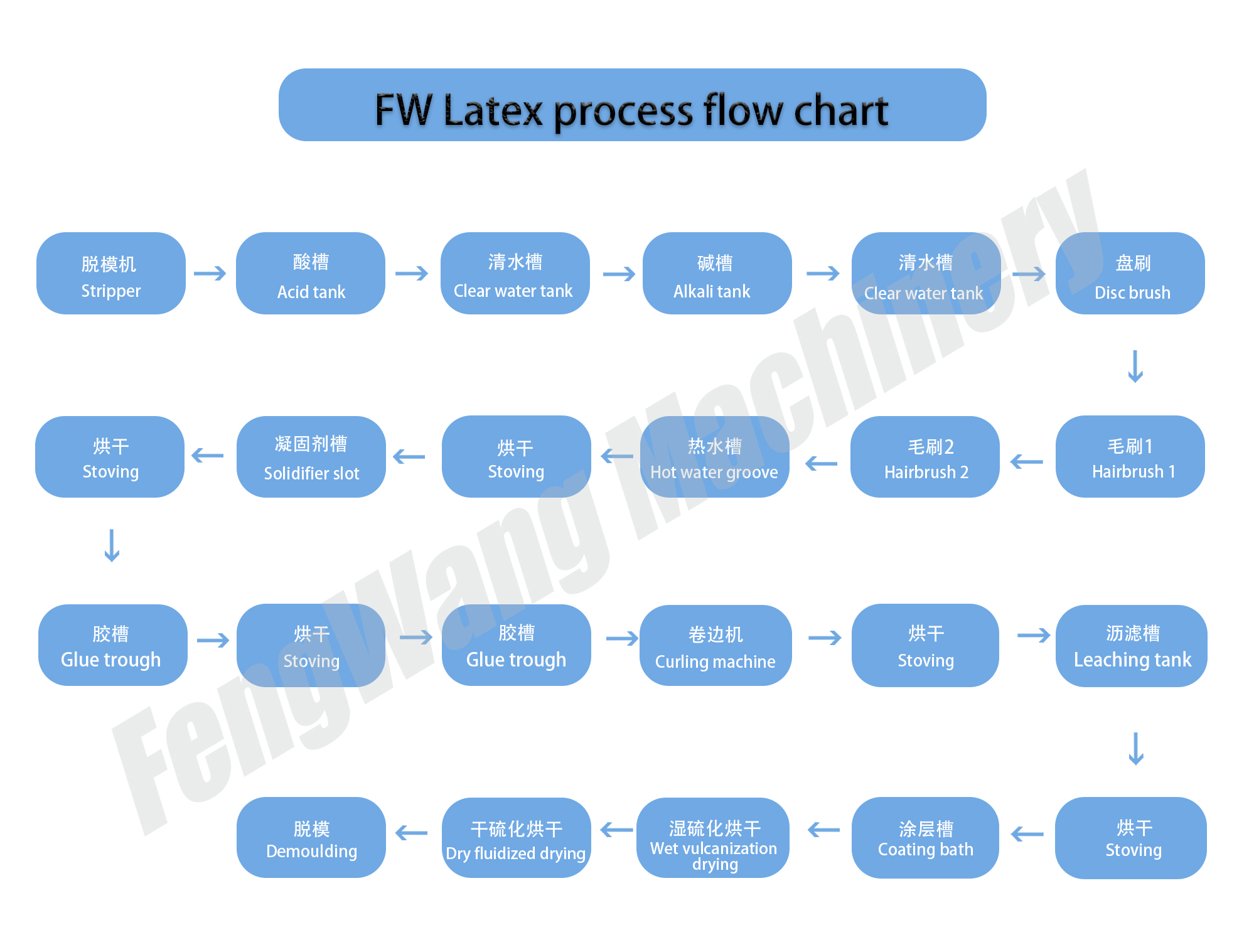

Nitrile Glove Manufacturing Process

Nitrile gloves production line is a complete set of modern fully automatic intelligent nitrile gloves machinery.

- Usually, glove formers are soaked in acid and alkali tanks and washed with acid and alkali water to remove dirt and debris from the hand formers.

- Cleaned glove formers are impregnated with a mixture of calcium nitrate and carbonate or calcium stearate to facilitate the separation of gloves and hand formers.

- Soak the hand mold in hot water to remove residual latex proteins and chemicals.

- The hand mold goes into the oven to be dried and cured, and the gloves are treated with fluorine or composite coating to control the surface grip characteristics.

- Dry. After drying, soak gloves to filter out excess latex protein.

- The hand model passes through the glove beading machine so that the cuff of the glove is rolled up and the glove is easier to carry.

- After the finished gloves go through the automatic glove stripping machine, the gloves are stripped off and transported and packaged after quality inspection, and finally sent to the customer.

Depending on the production speed of the glove production line, the entire glove manufacturing cycle takes about 40-60 minutes, after which the nitrile glove production cycle starts again.

After-sales Service

1. Service content

1) Overall design of glove production line.

2) Production line distribution diagram (including water, electricity and energy inlet layout of the production line).

3) Delivery schedule and installation schedule.

4) Production line equipment debugging.

5) On-site training in production line equipment maintenance and operation precautions.

2. Term and method of service

1) Service period: The company is responsible for providing free hardware (excluding wearing parts) within one year after the successful operation of the equipment, and implementing lifelong online after-sales service.

2) Service mode, if there is a problem with the system, you can notify our company by phone, social media or chat tools to clarify the problem, our response time is up to 1 hour, if the online problem cannot be solved, our staff will arrive at the customer’s factory for repair after consultation

3. Technical training and quality assurance measures

Technical training: After the production line is transported to the customer’s factory, our company is responsible for providing installation and technical training. The buyer’s technical personnel are familiar with the use of the system, and can deal with the problems in the operation of the system, so as to achieve orderly management and daily technical level maintenance.

4. Fee standard

Main parts (excluding wearing parts) one year free warranty and technical advisory services. After 1 year, free technical consultation service and paid on-site maintenance service are provided.