How to Make Nitrile Glove?

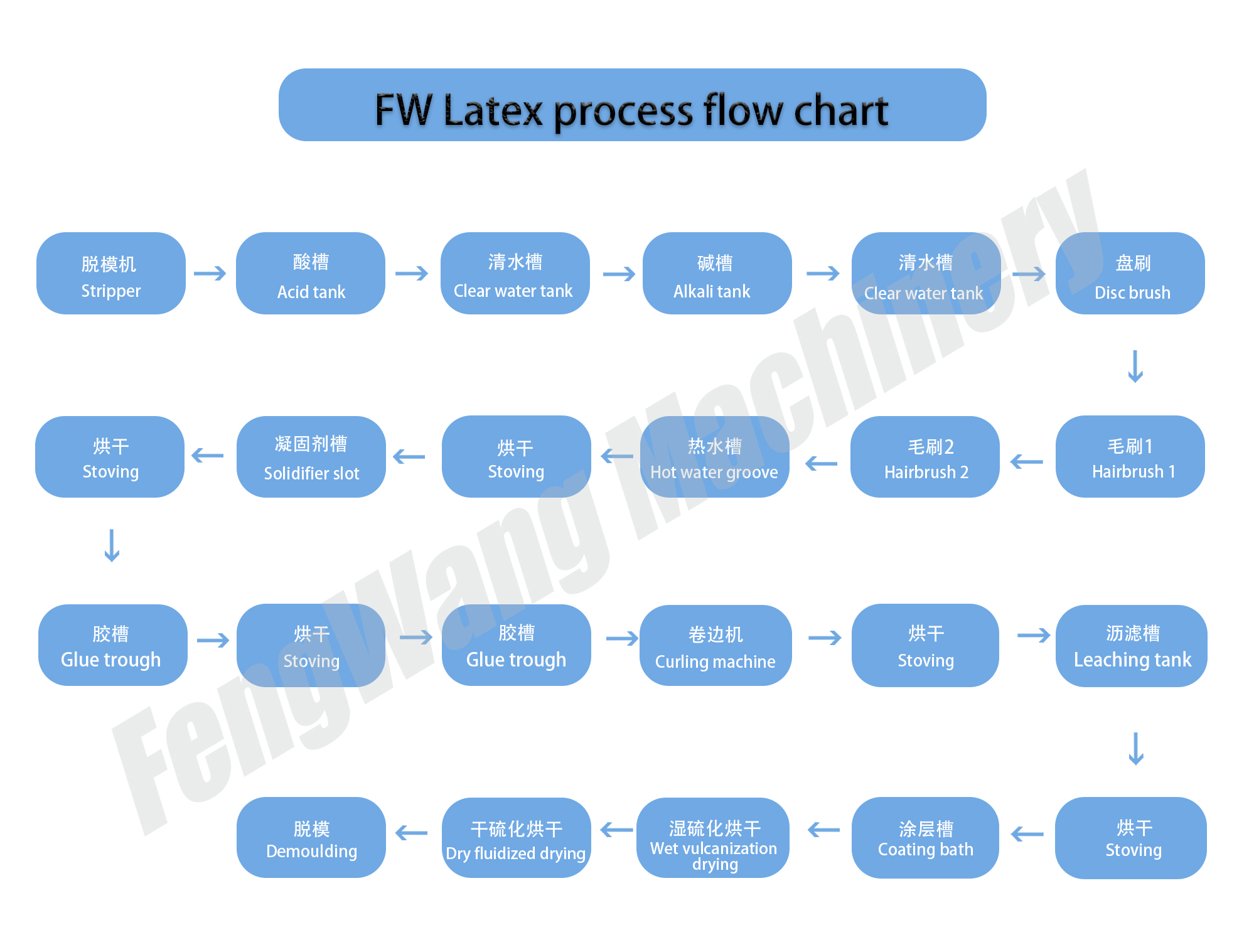

Nitrile gloves are made of synthetic rubber as the main raw material. After the glove former is dipped with raw materials, the glove former with nitrile glove is baked in the oven. After that, the glove former needs to be cooled down, and the glove is formed for the first time.

Gloves are usually coated with a polymer to make them easy to put on and take off. In addition, nitrile gloves have a certain degree of elasticity, providing a good grip, making them suitable for more sophisticated tasks.

Due to the unique advantages of their own material, nitrile gloves have better puncture and wear resistance and are more durable than latex and vinyl gloves. People often handle dangerous liquids and sharp objects according to this performance of nitrile gloves to ensure that users are protected from oil, chemicals, and harmful substances while safer handling relevant scenarios to avoid accidents.

A nitrile glove can be worn with the left or right hand; Gloves are treated with hemp surface to avoid slipping during use; After powder-free treatment, it is easy to wear and effectively avoid skin allergies caused by powder. Nitrile gloves are used in medical, pharmaceutical, health, beauty salon, food processing and other industries to prevent cross infection, and are essential hand protection products.

The physical testing of nitrile gloves is very important for the use case, in addition to the impact protection test, they also undergo tests such as “current cutting test” and “TDM-100 cutting test”. Gloves that pass these tests fall into the category of gloves that provide protection against mechanical risks and are considered to comply with the European standard EN 388.

Nitrile gloves production line parameters

Nitrile Glove Production Machine Features

Automatic nitrile glove making machine is the latest automatic intelligent nitrile glove production line equipment of Fengwang. It belongs to non-standard custom products, we provide drawings design, which can be customized according to the length, width and height of the customer’s workshop. Nitrile glove production machine is divided into single mode and double mode. The advantage of the nitrile glove single mold production machine is that it is more convenient to change the hand mold, and the advantage of the automatic nitrile glove double mold manufacturing machine is high output.

The nitrile glove production line provided by Fengwang consumes less labor, has low defective product rate, and has perfect after-sales service system. Chlorinated nitrile gloves can prevent adhesion. Compared with powdered nitrile gloves, powderless nitrile gloves have a wider application scenario, expanding the practical range of nitrile gloves.

In addition, Fengwang technicians remind nitrile glove manufacturers: it is recommended to clean the material tank of the production line every half month. Otherwise, there will be condensation in the material tank.

Nitrile Gloves Production Line Installation

1. The entire frame of the nitrile glove production line is made of steel structure to ensure the durability of the entire nitrile glove production line.

2. The length of the workshop required for the nitrile glove production line needs to be at least 10 meters longer than the length of the nitrile glove production line, the width is at least 15-20 meters longer than the width of the disposable glove production line, and the height is 1.5 meters higher than the production line height.

3. Maintenance of nitrile gloves manufacturing machine mainly includes hand mold replacement, chain slider lubricating oil replacement, brush replacement, valve repair, electrical repair, etc.

4. If the customer wants to get an accurate nitrile gloves production line quotation, or wants to know the accurate nitrile gloves manufacturing plant cost, the customer needs to provide the site plan of the nitrile gloves workshop. In addition, the production of nitrile gloves also requires customers to supply water, electricity, natural gas, coal, diesel and so on to the factory.

5. Wastewater treatment of nitrile glove production line

1> Find a local environmental protection company to provide water treatment equipment

2> The manufacturer dug several reservoirs by itself, which are: neutralization (adding the corresponding chemical substances and chemical residues in the wastewater), deepening (adding chemical additives to the wastewater), precipitation (natural precipitation of chemical residues in the wastewater), drainage (after the tank water and chemical wastewater are stratified, the upper water is directly discharged).